Enabling Warehouse Robotics with RF Interconnects

Enabling Warehouse Robotics with RF Interconnects

Autonomy within the warehouse logistics ecosystem facilitates efficiency, reduces cost and helps to ensure safety. Using autonomous mobile robots (AMRs) further boosts productivity and decreases damage during cargo handling. Amphenol RF interconnects deliver optimal warehouse robotic solutions and are central to industrial IoT.

A small warehouse with one robot in 2022 grows into a larger warehouse with multiple robots by 2030

Global warehouse automation market accounted for $19B in 2021 and is estimated to reach $64B by 2030 with a CAGR of 14.8% from 2022 to 2030

– Acumen Research & Consulting

Autonomous Mobile Robot market size was valued at $1.61B in 2021 and forecasted to reach $22.15B by 2030 with a CAGR of 34.3% from 2022–2030

– ResearchandMarkets.com

36,000 AMR in use in 2019 will grow to over 1.1M in use by 2024

– Robotics Week

Types of AMRs at Work

- Forklifts

- Load Transfers & Transporters

- Pallet Trucks

- Assembly Line

- Pickers

- Tuggers

Four Main AMR Job Functions in Logistics

- Order Picking

- Goods to Person

- Flexible Sortation

- Pallet Handling

Order Picking

Goods to Person

Flexible Sortation

Pallet Handling

Leading AMR Advantages

Boost picking performance by 2–3X

Reduce order errors

Lower human labor costs

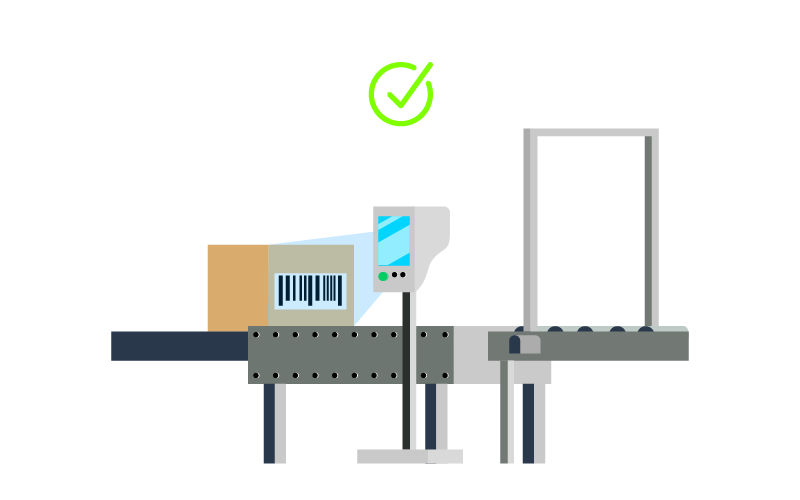

Specific RF Interconnect Applications

- Navigation (LiDAR)

- Collision Avoidance (mmWave)

- Camera & Vision Systems

- Cellular (4G, LTE, 5G)

- Wi-Fi & Wi-Fi 6/6E

- BLUETOOTH®

Türkiye

Türkiye