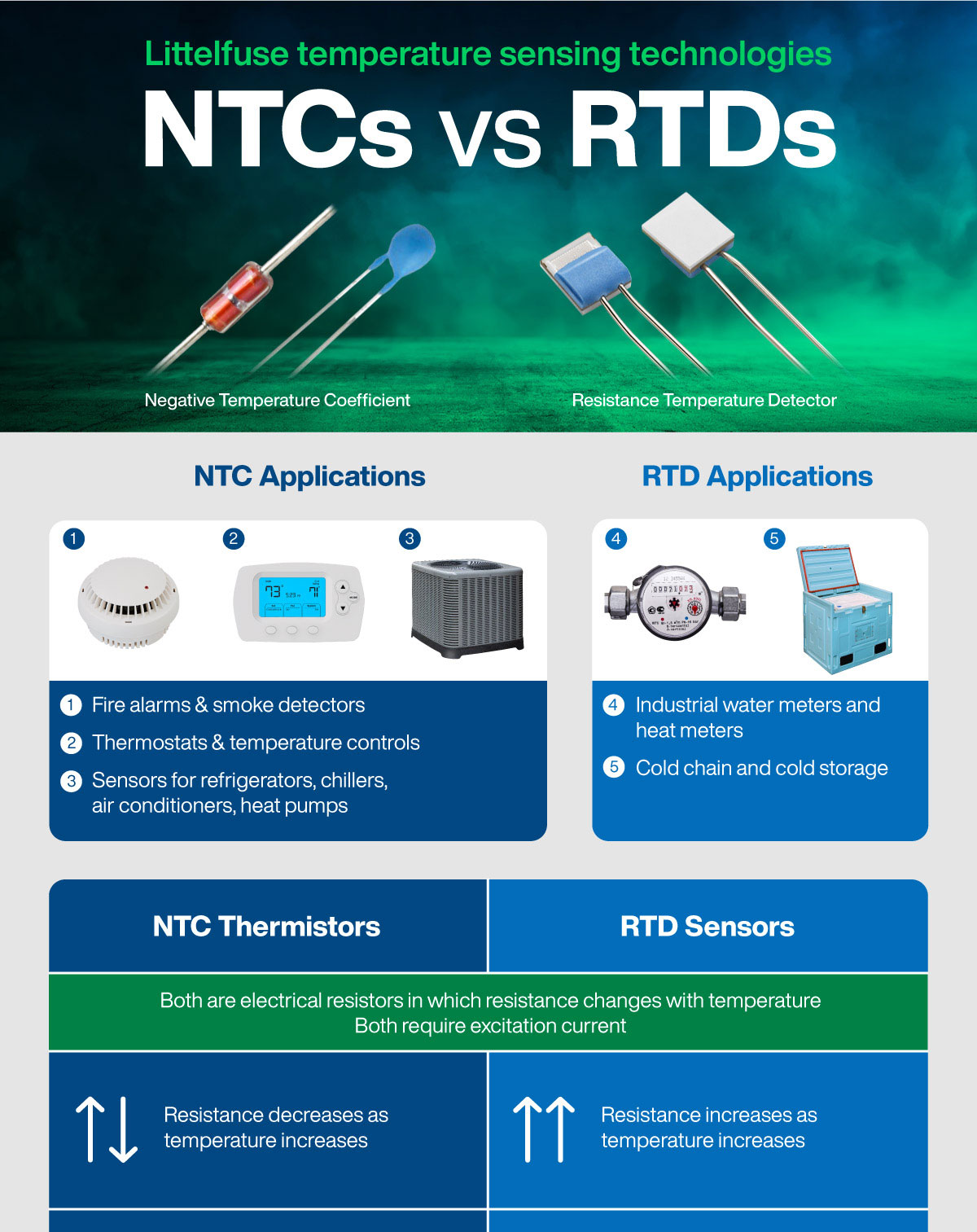

Littelfuse temperature sensing technologies

NTCs vs RTDs

- NTC: Negative temperature coefficient

- RTD: Resistance temperature detector

NTC applications:

- Fire alarms and smoke detectors

- Thermostats and temperature controls

- Sensors for refrigerators, chillers, air conditioners, heat pumps

RTD applications:

- Industrial water meters and heat meters

- Cold chain and cold storage

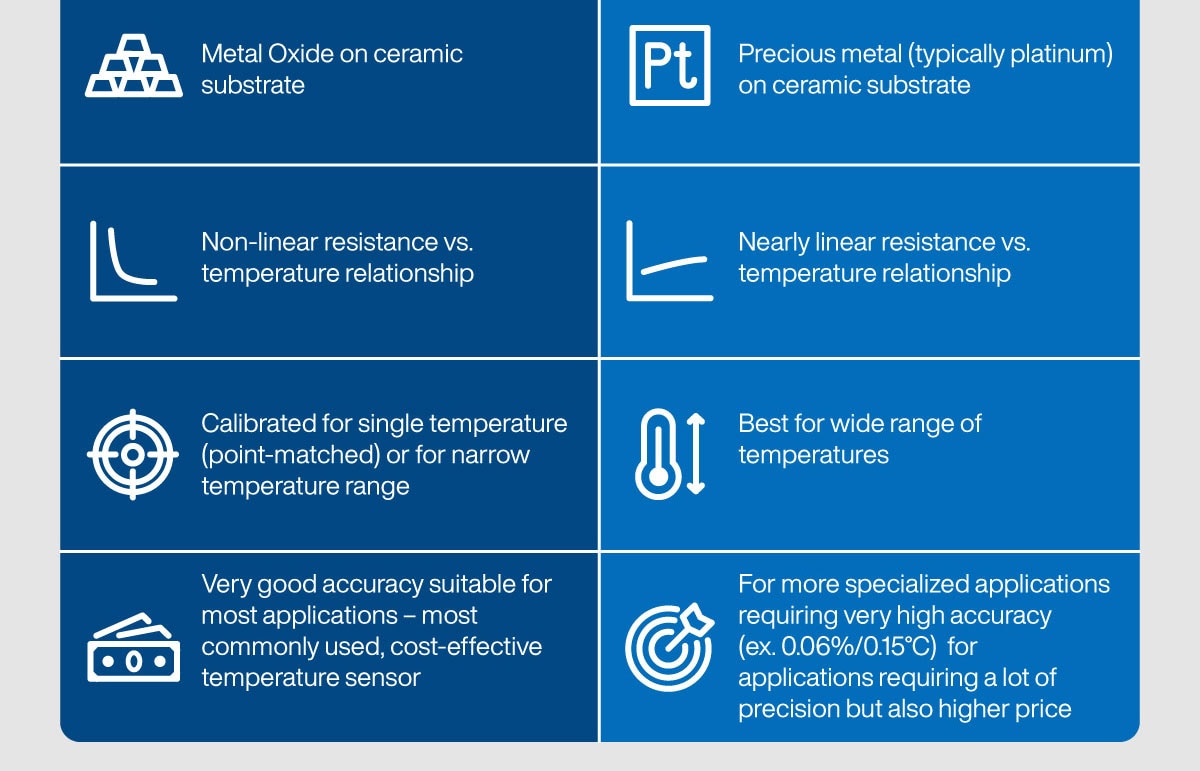

Chart comparing NTCs and RTDs

Both are electrical resistors in which resistance changes with temperature. Both require excitation current.

NTC thermistors:

- Resistance decreases as temperature increases

- Metal Oxide on ceramic substrate

- Non-linear resistance vs. temperature relationship

- Calibrated for single temperature (point-matched) or for narrow temperature range

- Very good accuracy suitable for most applciations—most commonly used, cost-effective temperature sensor

RTD sensors:

- Resistance increases as temperature increases

- Precious metal (typically platinum) on ceramic substrate

- Nearly linear resistance vs. temperature relationship

- Best for wide range of temperatures

- For more specialized applications requiring very high accuracy (ex: 0.06%/0.15℃C) for applications requiring a lot of precision but also higher price

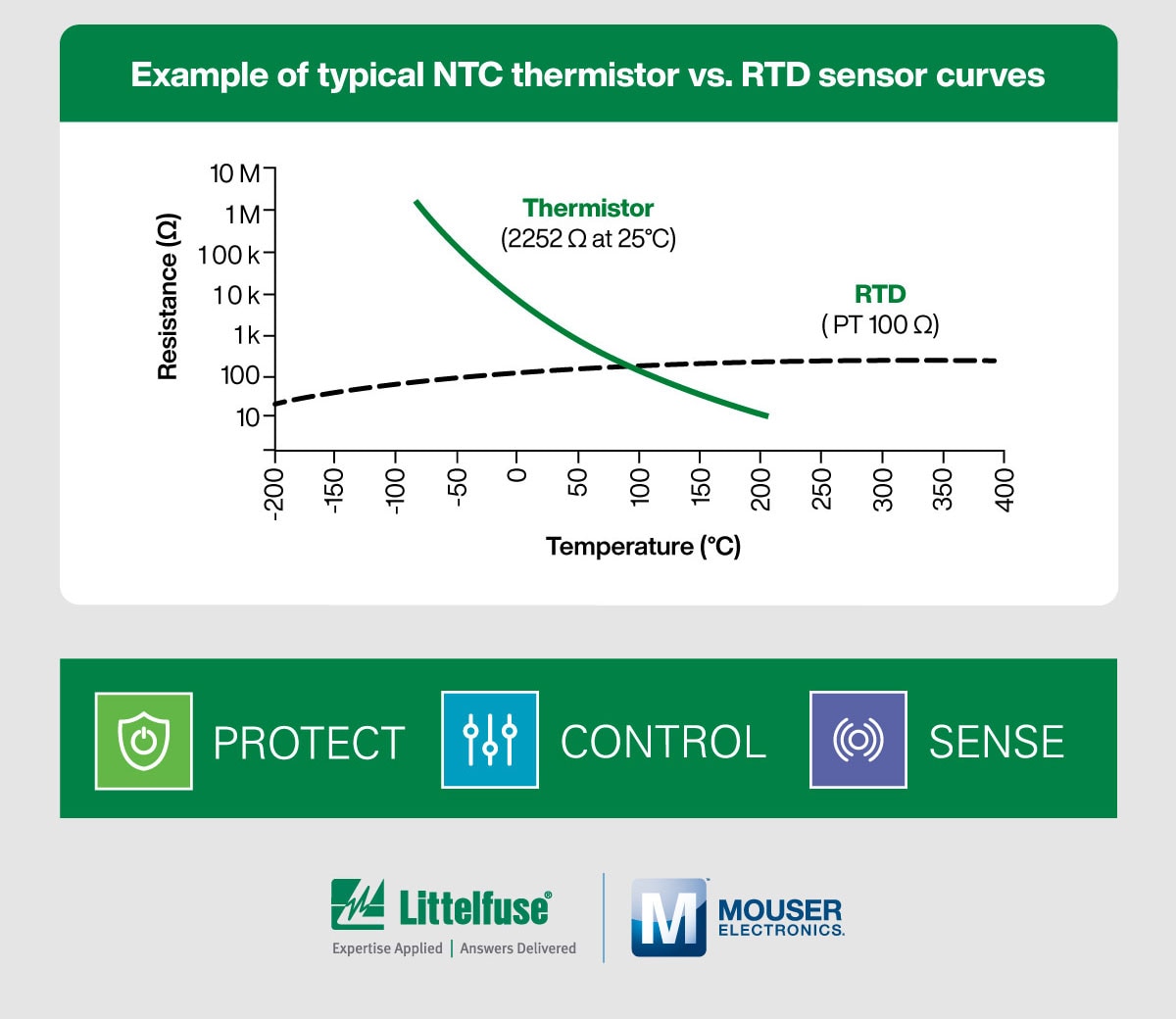

Chart showing an example of typical NTC thermistor vs. RTD sensor curves:

- Temperature (℃C) on the x-axis and resistance (Ω) on the y-axis

- RTD (PT 100 Ω) gradually increases almost lineraly as temperature rises

- Thermistor(2252 Ω at 25℃C) starts with a high resistance at a low temperature and decreases non-linearly as temperature rises

Türkiye

Türkiye